Description

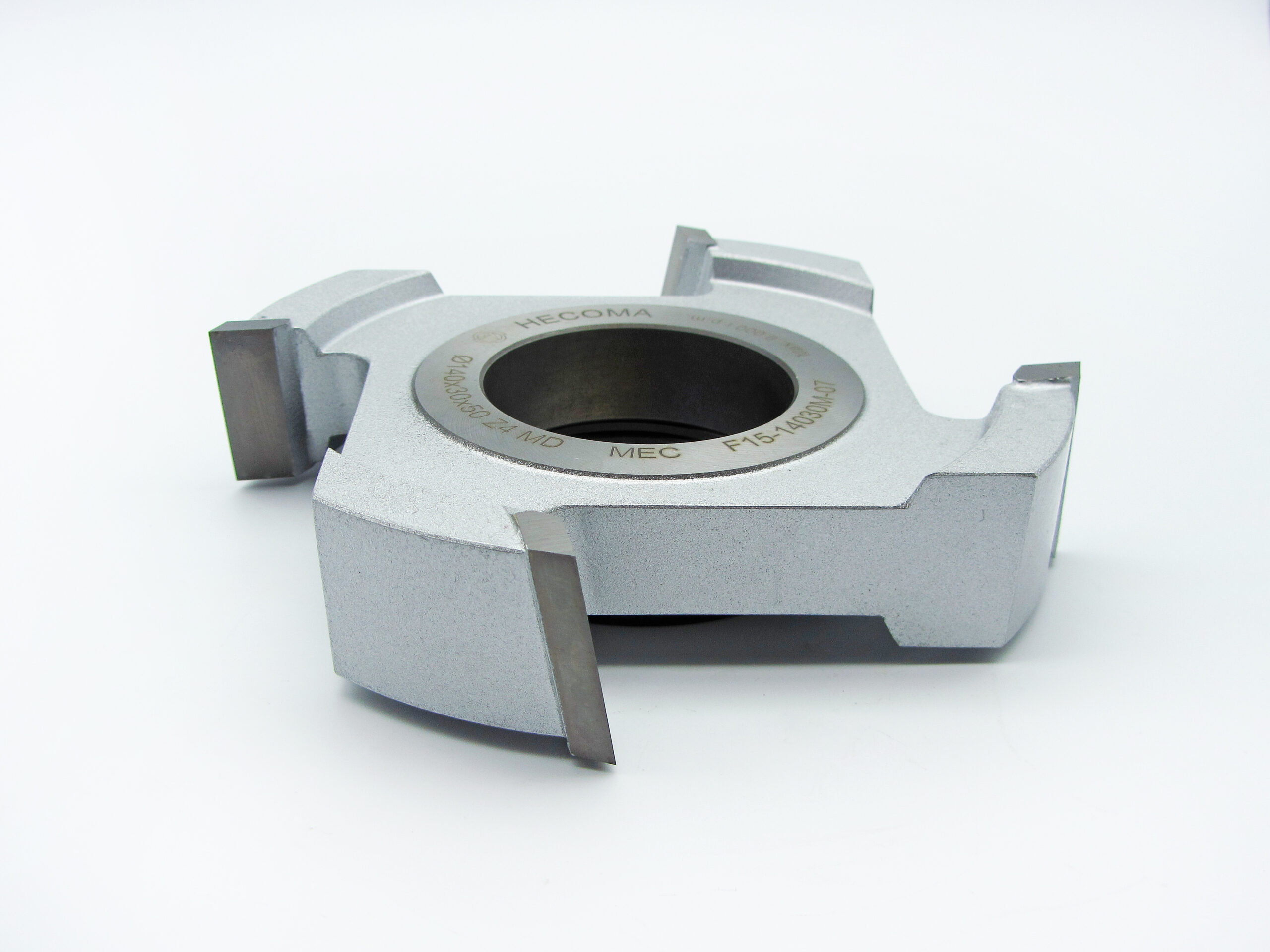

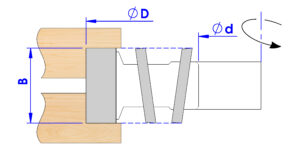

F15 Milling cutter for machining rebates with 4 alternating axial cuts

Characteristics of the tool :

- 4 alternating axial cuts (Z), for less vibration, better finish and feed.

- Made of MD (tungsten carbide) for hard or medium materials, and HSS (hardened steel alloys) for soft woods.

- Manufactured for use with mechanical feed.

Application

Tool for working rebates and edges in any type of wood, it provides better feed and works with less vibrations than the reference F14. The body is made of special steel alloy, durable and with better vibration absorption. The cutting plates (in tungsten carbide) are welded with a tri-metal alloy. We use the best materials and high-precision CNC for high performance, stable cutting quality and long cutting edge life. The milling cutter is delivered with the necessary instructions for its correct use.

This milling cutter is part of the professional express tool series (ProEx). It is available in the sizes shown in the table in our hardware and carpentry distributors.

Available references

The references shaded in grey are available immediately, the rest of them in a maximum of 72h. If you need other sizes, we can manufacture them according to your specifications, also in a very short period of time. Please contact us.

|

Ø mm |

B |

d |

Z |

Ref. en MD |

Ref. en HSS |

|

120 |

20 |

50 |

4 |

F15-12020M |

F15-12020H |

|

120 |

30 |

50 |

4 |

F15-12030M |

F15-12030H |

|

120 |

40 |

50 |

4 |

F15-12040M |

F15-12040H |

|

120 |

50 |

50 |

4 |

F15-12050M |

F15-12050H |

|

140 |

20 |

50 |

4 |

F15-14020M |

F15-14020H |

|

140 |

30 |

50 |

4 |

F15-14030M |

F15-14030H |

|

140 |

40 |

50 |

4 |

F15-14040M |

F15-14040H |

|

140 |

50 |

50 |

4 |

F15-14050M |

F15-14050H |

|

160 |

20 |

50 |

4 |

F15-16020M |

F15-16020H |

|

160 |

30 |

50 |

4 |

F15-16030M |

F15-16030H |

|

160 |

40 |

50 |

4 |

F15-16040M |

F15-16040H |

|

160 |

50 |

50 |

4 |

F15-16050M |

F15-16050H |