Get the most out of your tool with HECOMA®.

How do we get the maximum profitability out of our wood cutting tool?

Maximum profitability is achieved by taking into account the following factors: suitability, correct use and proper maintenance. Let’s take a closer look at each of them.

Adequacy of the tool

HECOMA® manufactures its wood cutting tools specifically for the work to be carried out. In other words, each tool is manufactured knowing the work the customer wishes to carry out, the material to be worked, the machine where the tool is to be installed, the speed at which it is to be worked, etc. All these factors are DETERMINANT for the design and manufacture of the tool.

Therefore, in order to obtain performance and durability from the tool we acquire, the first thing to do is to transmit as much information as possible to the manufacturer.

Correct use of the tool

As well as selecting the right tool for the job, it is very important to use it correctly. Again, many factors come into play here, but the most important thing is to use the tool only for what it was designed for:

- Speed ranges adjusted to those indicated, both in feed and RPMs.

- Materials. The tool is designed to work with a type of materials depending on their abrasiveness, hardness and compositions. Using the tool for other materials can produce a poor quality finish and significantly shorten the life of the tool.

- Machine model. Each machine has its own working specifications, and as we know, the tool was manufactured and designed with this in mind.

- Periodic cleaning with the right product for the job. By removing adhesive residues, varnishes, resins, etc. we manage to maintain the tool with its original characteristics of heat evaporation, balancing and chip evacuation.

Maintenance

Regrinding, repair and adjustment of cutting surfaces. This is the critical factor and the quality of this work determines the performance and life of your tool.

At HECOMA® our main objective is THE PROFITABILITY OF YOUR TOOL. This is not a commercial slogan, it is our differentiating value.

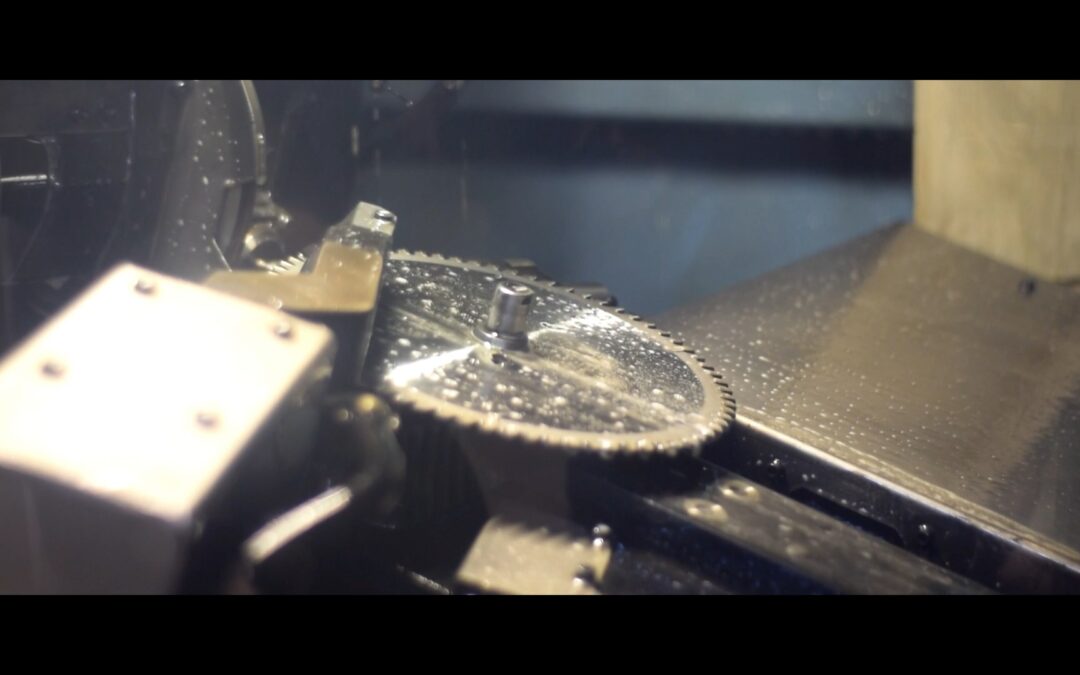

With qualified and experienced personnel, the most advanced machinery, a conscientious sharpening, with the necessary care and passes, with a subsequent rebalancing and with the adjustment of the cutting surfaces so that they all work correctly, we provide you with a service of the highest quality. A work that is conscious of the aim to be achieved: QUALITY and PERFORMANCE.

A professional sharpening job provides you with the profitability you are looking for, due to the proper functioning of the tool in your machine, the quality of its finish, the number of re-sharpenings possible and the long life of the cutting edge after re-sharpening.

If you use your tool for fine work, you are looking for the best finish and to extend the life of your tool, we advise you to sharpen it often instead of “rushing” it to the maximum before each sharpening:

- The condition of the cutting edge is decisive for the finish and the working speed.

- Re-sharpening will be quicker and less costly.

- Minimise the possibility of damage to cutting surfaces

- Sharpening will require less material to be removed, so your tool can be re-sharpened many more times.

In short, your tool will give you maximum performance for longer, significantly increasing the profitability of your tool.

HECOMA® Cutting Tool Services – profitability for your business.

contact with HECOMA®

We manufacture tools for perfect performance